-40%

New Era Model NE-1660 Digital Multi Syringe 6-Channel Syringe Pump

$ 473.22

- Description

- Size Guide

Description

FREE EXPEDITED SHIPPING FOR ORDERS of 0 and ABOVE!!!(EXPEDITED SHIPPING MUST BE SELECTED UPON CHECKOUT)

_________________________________________________________

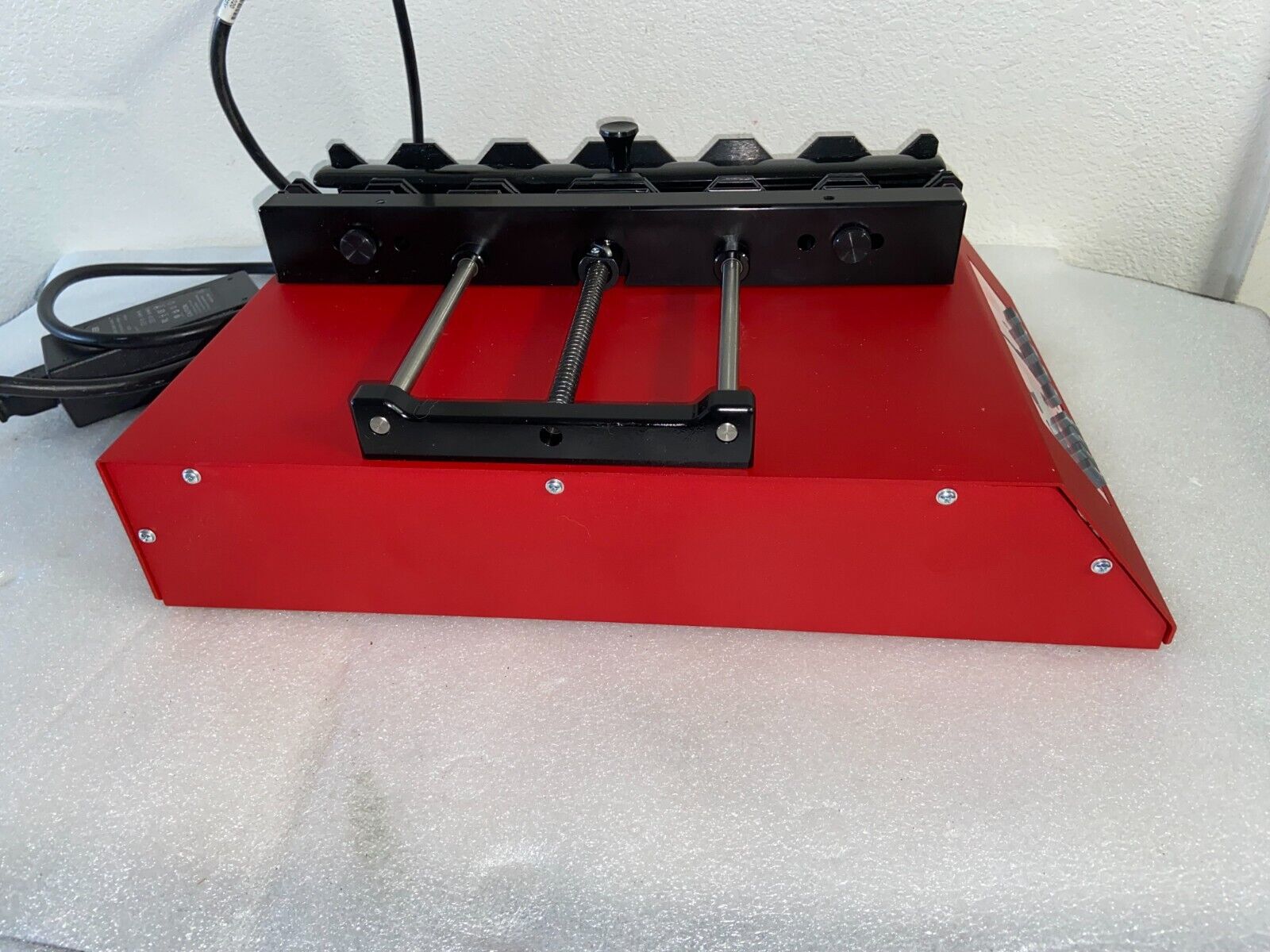

New and Unused New Era Model NE-1660 Digital Programmable Multi Syringe 6-Channel Syringe Pump, with Power Supply.

We do not have the original box for the item.

New Era NE-1660 Programmable Six Channel Syringe Pump

Features:

Holds 2, 4, or 6 syringes of up to 140 mL each

Infusion rates from 0.452 µL/hr (1 mL syringe) to 1451 mL/hr (60 mL syringe)

Easy-to-use keypad interface

One-click program upload from ""Pumping Program Generator"" spreadsheet

Higher flow rate models available

Includes all the advanced functions and programming features of the NE-1000 series

Disposable, Glass, Stainless Steel Syringes and Plumbing Supplies are sold separately.

Fully programmable; automation capable

Operates stand-alone or from a computer. Cables sold separately.

Infusion and withdrawal

Set a single pumping rate and/or dispensing volume

Program up to 41 pumping phases that change pumping rates, set dispensing volumes, insert pauses, control and respond to external signals, sound the buzzer

Network, control, and monitor up to 100 pumps with one computer

Worldwide power supplies available

Motor stall detection

Dispensing accuracy of +/-1%

Unlimited lifetime technical support

Two year warranty

Example Flow Rates (NE-1600):

Syringe Size

Maximum Rate

Minimum Rate

0.5 µL

17.45 µL/hr

0.001 µL/hr

1 mL

36.19 mL/hr

0.452 µL/hr

3 mL

153.2 mL/hr

1.914 µL/hr

5 mL

255 mL/hr

3.185 µL/hr

10 mL

415.9 mL/hr

5.195 µL/hr

20 mL

661.4 mL/hr

8.26 µL/hr

30 mL

862.8 mL/hr

10.78 µL/hr

60 mL

1451 mL/hr

18.1 µL/hr

140 mL

2376 mL/hr

29.7 µL/hr

Pump Programming:

One-click program upload from ""Pumping Program Generator"" spreadsheet

Up to 340 programmable phases

Enter programs from the keypad or from a computer.

Download or upload pumping programs from or to a computer. Store dispensing programs in a file on your computer, then upload them to one or more pumps. Specify in the file to send a different pumping program to each pump in the pump network.

Pre-program dispense volumes. Each volume can be different.

Automatically change pumping rates or pumping direction.

Ramp up or down the pumping rate.

Set timed delays between dispenses.

Automatically pause the program and wait for the user to continue the dispense.

Synchronize dispenses with other equipment or pumps to change pumping rates in reaction to a sensor or signals from other pumps.

Send logic signals to other equipment. Change pumping rates in reaction to a sensor.

Program the audible alarm to beep at any time to alert the operator.

Bi-Directional RS-232 Interface

Network up to 100 pumps from a single communications port on a computer. Baud rates up to 19200.

Free terminal emulator program allows communications with syringe pump.

Directly control one or more pumps from a computer, including setting the pumping rate, direction and volume. Set the operational and setup configurations. Also the TTL interface can be queried and the programmable output set.

Using a computer, each pump in the pump network can be individually controlled and monitored. Or, the computer can download a new pumping program to each pump which would automatically reconfigure the dispensing system for a new job.

Downloading control programs to the pump would unload computer overhead to the pump. computer resources could then be used elsewhere while the pumps operate independently.

2 modes of communications: Basic and Safe

Basic: Basic master-slave interface. Easy to implement. Can communicate from any terminal emulator.

Safe: A reliable interface for a real-world environment.

High quality interface which detects communication errors via a 16 bit CCITT CRC.

The pump will automatically transmit an alarm packet when a pump alarm occurs. For instance, if the pump stalls or resets, a message is immediately sent to the computer.

A configurable communications time-out will stop the pump and alarm if the communications link is broken.

Packet inter-character time-out to recover packet synchronization after communication glitches.

Software Developer friendly communications protocol.

Consistent and well defined communications packets.

Constant start and end characters.

Packets structured to be easily parsed

TTL Logic Contol Interface

Control the pump from a foot switch or timer.

Output signals can be used to switch a valve from an output to an input reservoir.

Keypad Lockout: Prevent unauthorized or accidental changes to the settings by requiring a ""Lockout Disable"" key to be inserted to change settings.

Pumping direction control

Programmable output signal

Programmable responses to input signals

Configurable start and stop trigger:

Start or stop the pump on each contact closure to ground. For example, a foot switch.

Start the pump on closure to ground and stop the pump on opening the connection. For example a timer relay that starts the pump whenever closed and stops the pump whenever open.

Only start the pump on each contact closure to ground. For example, a laboratory animal trained to press a lever can receive a drug dosage from the pump and the pump will not stop or deliver another dosage until it is permitted by the pumping program entered by the user

Configurable trigger input:

Edge trigger: Starts or stops the pump, such as from a foot switch

Level trigger: Start or stops the pump, such as from a timer or relay control

Start only trigger: Edge trigger will only start the pump, such as from a lab animal trained to press a lever to receive a dosage.

"